Leading Film Faced Plywood Manufacturing

Leading Film Faced Plywood Manufacturing

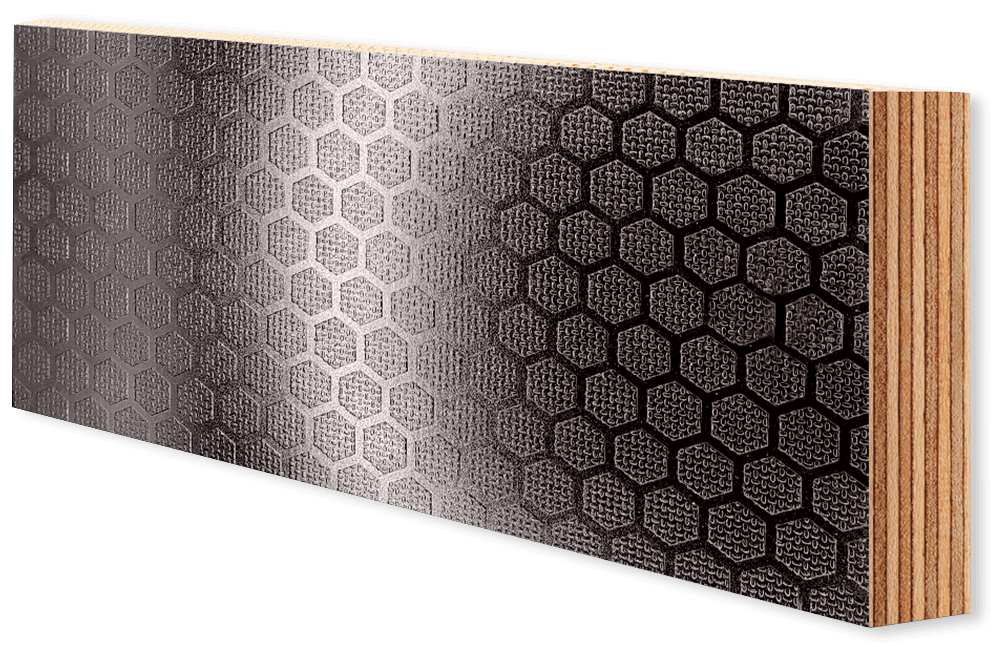

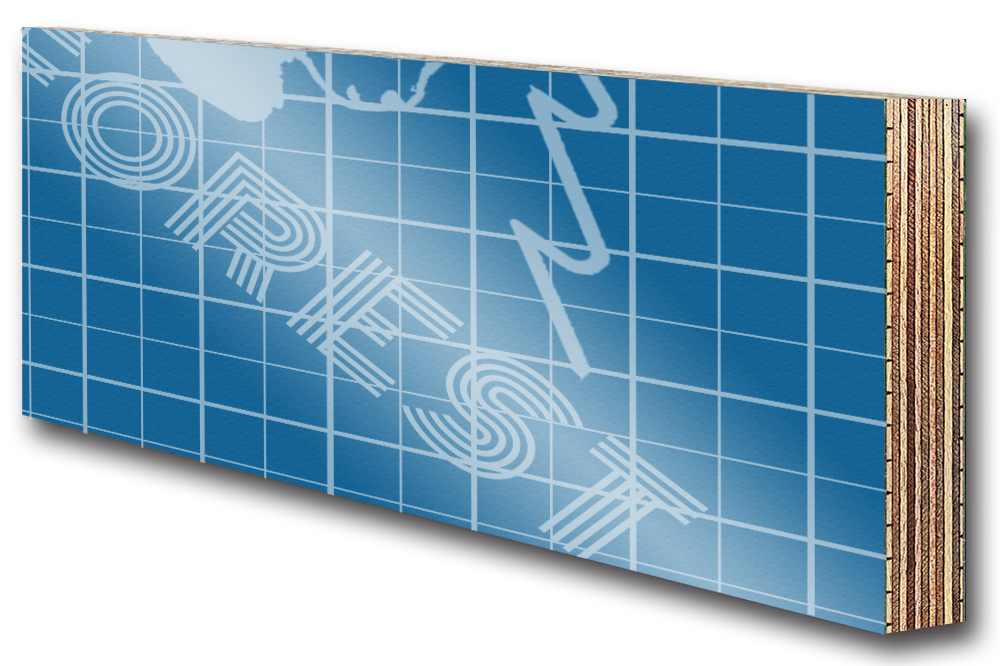

PANDAforest PP Plastic Plywood It is a kind of durable composite plastic coated plywood for more than 80 times reuse life under correct guidance, which verified by engineering projects and experts.

Full Hardwood veneers are arranged crosswise according to mechanical properties. Miter joint and hot melt wire connection are adopted to avoid excessive gap and ensure excellent hardness and stability.

The edges 4 times sealed with waterproof paint in the factory for minimise moisture penetration.

Deep penetration, locking each layer of veneer. Special custom-made phenolic adhesives cross-bonded weather resistant glueing according to EN 314-2 / class 6.

Double surface is smooth, glossy and hard.

Exceedingly resistant to moisture, cold, UV radiation, acids, alkalis, rotting and fungal decay.

Light weight and easy cut.

Excellent strength and durability.

Exact size, Can be customized to your needs sharps.

Reduces work time and labor costs

Support FSC and PEFC legally harvested resources.

Support OEM/ ODM service.

Building & construction

Vehicle industry

Internal & external design

Hoardings and fencings

Packing

The surface of PADANforest plastic plywood is acid and alkali resistant, anti-corrosion, waterproof and wear-resistant. Available in three common colors for choose – Green, Blue and grey. Plastic layers 0.5mm thick, Wear resistance value from 2500 R to 3000 R (EN 438-2) depending on the coating.

Don't hesitate to contact us for color customization. Contact Us

| Grade | Size | Weight (kg/sheet) | Core Materials | Packing Unit (sheets) | |||||||

| AA | 1220x2440x6mm | 11 | Full Birch | 110 or 135 | |||||||

| AA | 1220x2440x9mm | 16.5 | Full Birch | 75 or 90 | |||||||

| AA | 1220x2440x12mm | 22 | Full Birch | 55 or 67 | |||||||

| AA | 1220x2440x15mm | 27.5 | Full Birch | 45 or 54 | |||||||

| AA | 1220x2440x18mm | 33 | Full Birch | 37 or 45 | |||||||

| AA | 1220x2440x21mm | 38.5 | Full Birch | 32 or 39 | |||||||

| AA | 1220x2440x25mm | 46 | Full Birch | 27 or 32 |

| Grade | Size | Weight (kg/sheet) | Core Materials | Packing Unit (sheets) | |||||||

| AA | 1250x2500x6mm | 11.5 | Full Birch | 110 or 135 | |||||||

| AA | 1250x2500x9mm | 17.5 | Full Birch | 75 or 90 | |||||||

| AA | 1250x2500x12mm | 23 | Full Birch | 55 or 67 | |||||||

| AA | 1250x2500x15mm | 59 | Full Birch | 45 or 54 | |||||||

| AA | 1250x2500x18mm | 34.5 | Full Birch | 37 or 45 | |||||||

| AA | 1250x2500x21mm | 40.5 | Full Birch | 32 or 39 | |||||||

| AA | 1250x2500x25mm | 48.5 | Full Birch | 27 or 32 |

Apart from the regular standard dimensions of 1220mm x 2440mm and 1250mm x 2500mm, also special lengths are available (max width 2000mm and max lengrh 6000mm). Special dimensions available by request – there may be requirements for minimum quantity per special dimension.

We can provide OEM orders according to your requirements and work with you to build your own film faced plywood brand. Please contact our OEM Service Team.

China Forest Products Supply Co., Ltd.