Leading Film Faced Plywood Manufacturing

Leading Film Faced Plywood Manufacturing

PANDAforest film faced plywood birch is building templates recommended by numerous global architects, PANDAforest film faced plywood birch is a universal casting plywood panel that can be used for many different applications, from frame system to special template system. Dynea-Aica (a world-renowned plywood adhesives brand) supplies PANDAforst with custom-made phenolic adhesives and waterproof film.

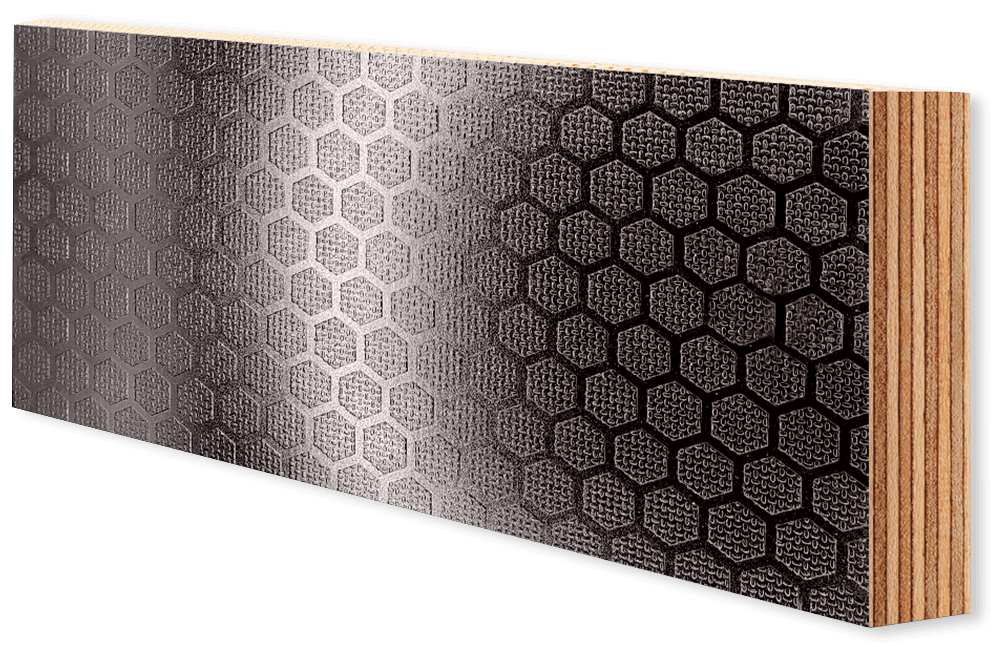

Dark brown phenolic film 120 g/m2 or 220g/m2. Smooth and flat surface on both sides, solid, waterproof and wear-resistant. The film-faced surface of the panel creates high stability to various natural and chemical conditions.Easy Build high-quality flat concrete surfaces.

Full birch veneers are arranged crosswise according to mechanical properties. Miter joint and hot melt wire connection are adopted to avoid excessive gap and ensure excellent hardness and stability.

The edges 4 times sealed with waterproof paint in the factory for minimise moisture penetration. Grey edge red stripe.

Deep penetration, locking each layer of veneer. Special custom-made phenolic adhesives cross-bonded weather resistant glueing according to EN 314-2 / class 6.

Smooth and wear-resistant on both sides.

Excellent strength and durability.

Stable mechanical properties.

Can be customized to your needs.

Economical and environmentally friendly.

Support FSC and PEFC legally harvested resources.

Support OEM/ ODM service.

Horizontal formwork

Vertical formwork

Special formwork

Frame formwork systems

DIY

| Grade | Size | Weight (kg/sheet) | Core Materials | Packing Unit (sheets) | |||||||

| AA | 1220x2440x6mm | 12.85 | Full Birch | 110 or 135 | |||||||

| AA | 1220x2440x9mm | 19 | Full Birch | 75 or 90 | |||||||

| AA | 1220x2440x12mm | 25.5 | Full Birch | 55 or 67 | |||||||

| AA | 1220x2440x15mm | 32 | Full Birch | 45 or 54 | |||||||

| AA | 1220x2440x18mm | 38.5 | Full Birch | 37 or 45 | |||||||

| AA | 1220x2440x21mm | 45 | Full Birch | 32 or 39 | |||||||

| AA | 1220x2440x25mm | 53.5 | Full Birch | 27 or 32 |

| Grade | Size | Weight (kg/sheet) | Core Materials | Packing Unit (sheets) | |||||||

| AA | 1250x2500x6mm | 13.5 | Full Birch | 110 or 135 | |||||||

| AA | 1250x2500x9mm | 20 | Full Birch | 75 or 90 | |||||||

| AA | 1250x2500x12mm | 27 | Full Birch | 55 or 67 | |||||||

| AA | 1250x2500x15mm | 33.5 | Full Birch | 45 or 54 | |||||||

| AA | 1250x2500x18mm | 40.5 | Full Birch | 37 or 45 | |||||||

| AA | 1250x2500x21mm | 47 | Full Birch | 32 or 39 | |||||||

| AA | 1250x2500x25mm | 56 | Full Birch | 27 or 32 |

We can provide OEM orders according to your requirements and work with you to build your own film faced plywood brand. Please contact our OEM Service Team.

China Forest Products Supply Co., Ltd.