Leading Film Faced Plywood Manufacturing

Leading Film Faced Plywood Manufacturing

PANDAforest UV finished plywood is a special high quality prefinished Plywood. The features unique transparent coating effectively protect the natural texture of plywood, which is scratch resistant and wear-resistant. It is widely used in the manufacture of furniture and interior decoration. Due to the finished UV coating on the surface, it save time, manpower, equipment costs and waste in the production process of furniture and cabinet components.

Full birch veneers are arranged crosswise according to mechanical properties. Miter joint and hot melt wire connection are adopted to avoid excessive gap and ensure excellent hardness and stability.

The edges 4 times sealed with waterproof paint in the factory for minimise moisture penetration.

Deep penetration, locking each layer of veneer. Special custom-made phenolic adhesives cross-bonded weather resistant glueing according to EN 314-2 / class 6.

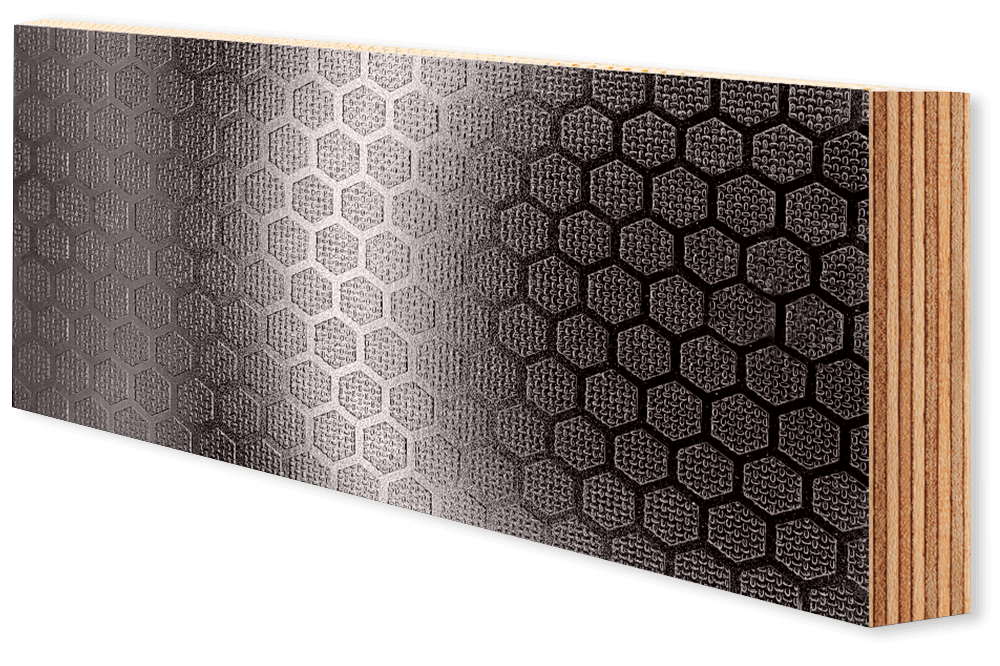

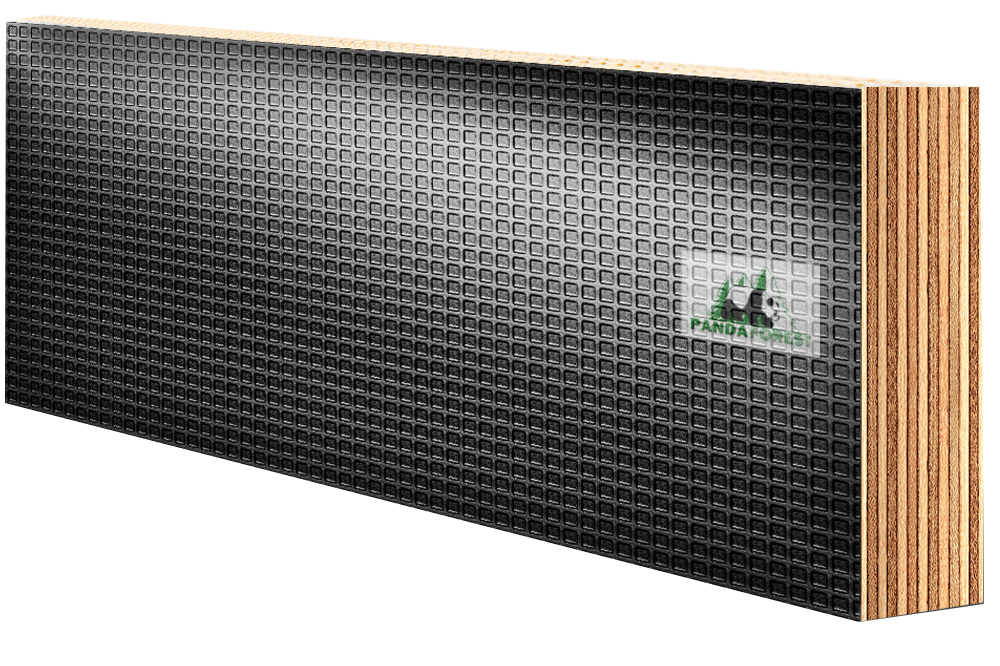

Slip-resistant and Wear resistant surface

Excellent strength and durability.

Stable mechanical properties.

Can be customized to your needs sharps.

Economical and environmentally friendly.

Support FSC and PEFC legally harvested resources.

Support OEM/ ODM service.

Vans Floor

Trailers Floor

Construction scaffolding

Stages, terraces

Sports fields and facilities

Playground structures and equipment

DIY

PADANforest - Antislip Trans plywood surface available in five common colors for choose – black, brown, grey, red and blue. Antislip coating density 220g/m2,can be made into single-sided anti-slip or double-sided anti-slip. Wear resistance value from 800 R to 1500 R (EN 438-2) depending on the coating.

| Grade | Size | Layer up | Weight (kg/sheet) | Core Materials | Packing Unit (sheets) | ||||||

| AA | 1220x2440x3mm | /=/ | 5.2 | Hardwood Plywood | 200 | ||||||

| AA | 1220x2440x5mm | /=/ | 8.5 | Hardwood / Combi | 120 | ||||||

| AA | 1220x2440x6mm | /=/ | 10.5 | Hardwood / Combi | 100 | ||||||

| AA | 1220x2440x9mm | /=/ | 15.5 | Hardwood / Combi | 70 | ||||||

| AA | 1220x2440x12mm | /=/ | 20.5 | Hardwood / Combi | 50 | ||||||

| AA | 1220x2440x15mm | /=/ | 25.5 | Hardwood / Combi | 40 | ||||||

| AA | 1220x2440x18mm | /=/ | 31 | Hardwood / Combi | 35 | ||||||

| AA | 1220x2440x21mm | /=/ | 36.5 | Hardwood / Combi | 30 | ||||||

| AA | 1220x2440x25mm | /=/ | 43 | Hardwood / Combi | 25 |

| Finish thickness dry:1.0 – 1.5 mil | |||||||||||

| Layer up:Cross-oriented | |||||||||||

| Moisture Content:8% – 15% (at time of despatch) | |||||||||||

| Dimensional Tolerances:±0.3mm | |||||||||||

| Straightness:±1.5mm | |||||||||||

| Density:650 kg/m³ (approximately) | |||||||||||

| Machinability:Excellent | |||||||||||

| VOC Emissions :None | |||||||||||

| Finish:Unsanded faces, sanding / T&G / Edge banding | |||||||||||

| Branding:Each pallet of PANDAFOREST plywood is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards | |||||||||||

| Storage:Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | |||||||||||

| Source:Plantation timber |

Apart from the regular standard dimensions of 1220mm x 2440mm,1250mm x 2500mm also special dimensions available by request – there may be requirements for minimum quantity per special dimension.

We can provide OEM orders according to your requirements and work with you to build your own film faced plywood brand. Please contact our OEM Service Team.

China Forest Products Supply Co., Ltd.

If you are interested in any of our products or would like to discuss a customized order, Please feel free to contact us.