Leading Film Faced Plywood Manufacturing

Leading Film Faced Plywood Manufacturing

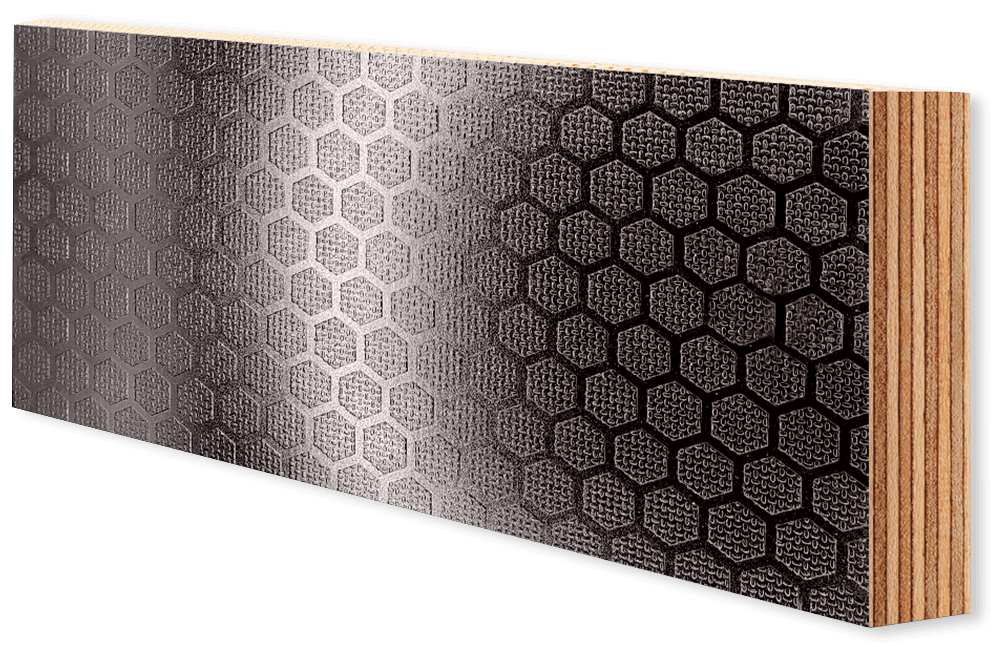

PANDAforest flexible plywood is one of the best lightweight bendable plywood panels.

Two structural type of PANDAforest Flexible Plywood:

Features and advantages

Strong, light and bendable

High strength to weight ratio.

Suitable for laser cutting and CNC machining

Cold forming with small radii (with no need for heat forming or water treatment).

Complex multi-radii shapes can be quickly and easily prepared.

The panels can simply be combined and glued together to create different thicknesses (10, 13, 15, 18, 20, 21 mm, etc.).

More convenient than other pre-made wood forms.

Reduction of material and labour costs to a minimum.

No need for special equipment or prior experience.

Smooth and hard surface.

Exact size with strict tolerances

Wide size and thickness range available.

Customized to your needs.

Support FSC and PEFC legally harvested resources. and is E1 emissions compliant.

Support OEM/ ODM service.

On the construction site, PANDAforest flexible plywood can be covered with a wide range of laminates or paper-backed veneers for the finished look you need.

Rounded furniture designs

Curved cabinet ends or islands

Reception and office work stations

Arches and arched casings

Rounded wall units and columns

| Grade | Size | Layer up | Weight (kg/sheet) | Core Materials | Packing Unit (sheets) | ||||||

| AA | 1220x2440x2.7mm | /-/ | 3.5 | Poplar / Hardwood / Combi | 285 or 350 | ||||||

| AA | 1220x2440x3mm | /-/ | 4 | Poplar / Hardwood / Combi | 250 or 300 | ||||||

| AA | 1220x2440x3.6mm | /-/ | 5.5 | Poplar / Hardwood / Combi | 190 or 225 | ||||||

| AA | 1220x2440x4mm | /-/ | 5.6 | Poplar / Hardwood / Combi | 215 or 250 | ||||||

| AA | 1220x2440x5.2mm | /-/ | 7 | Poplar / Hardwood / Combi | 145 or 170 | ||||||

| AA | 1220x2440x6mm | /-/ | 8 | Poplar / Hardwood / Combi | 125 or 155 | ||||||

| AA | 1220x2440x9mm | /-/ | 12 | Poplar / Hardwood / Combi | 85 or 100 | ||||||

| AA | 1220x2440x12mm | /-/-/-/ | 16 | Poplar / Hardwood / Combi | 65 or 75 |

Apart from the regular standard dimensions of 1220mm x 2440mm and 1250mm x 2500mm, also special lengths are available. Special dimensions available by request – there may be requirements for minimum quantity per special dimension.

We can provide OEM orders according to your requirements and work with you to build your own plywood brand. Please contact our OEM Service Team.

China Forest Products Supply Co., Ltd.