Leading Film Faced Plywood Manufacturing

Leading Film Faced Plywood Manufacturing

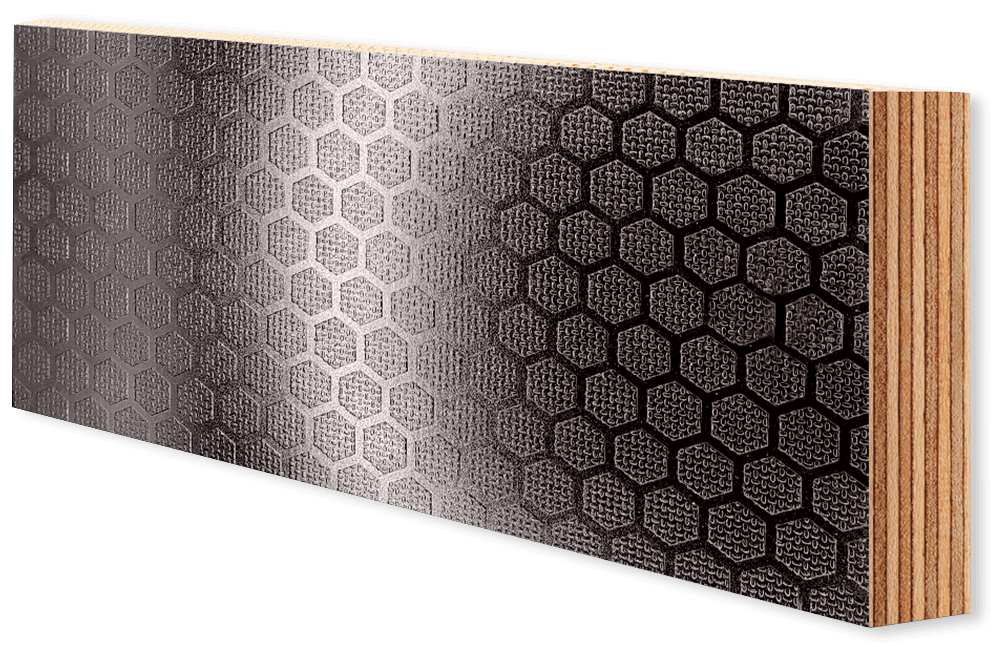

PANDAforest Tongue & Groove OSB ( T&G OSB ) is a highly engineered flooring panel made with three layers of micro-veneers that are cross-laid and hot-pressed using proven moisture-resistant resin systems. Fresh wood from managed forests is used, assuring that PANDAforest OSB is free of contamination.

◎ Faster and easier laying, saving time and cost

◎ High cost performance and low price.

◎ Smooth surface; no core voids, knots or splits.

◎ Good sound insulation, high stiffness and ability to withstand significant snow and wind loads allow to use.

◎ We have the flexibility to customize specific properties, lengths, widths.

◎ Edge seal helps prevent moisture intrusion and water-related issues that can lead to call backs.

◎ Suitable for uses not permanently exposed to the weather (exposure 1 panel).

◎ Available in 8-ft, 9-ft and 10-ft lengths.

◎ Available in tongue and groove profile for easy installation

◎ Environmentally safe construction material.

◎ High strength and stiffness

◎ Strong and uniform consistency throughout.

◎ Support FSC and PEFC legally harvested resources. and is E1 emissions compliant.

◎ Support OEM/ ODM service.

◎ Wall Sheathing - interior and exterior walls. OSB panels can be used with all types of interior and exterior finishing materials

◎ Roof sheathing- OSB panels as an underlayment for shingles, concrete and metal tiling, slating and other roofing materials.

◎ Subfloor - can be used both as continuous flooring and load bearing joists

◎ Single floor – in light structures OSB panel can be used directly as flooring.

◎ Furniture –frames of upholstered furniture, chairs, cabinet furniture, home built-in furniture (coat closets, shelving units, wall wardrobes)

◎ I-joists – supporting floor and wall structures in timber houses.

◎ SIP panels - Manufacturing consisting of two outer OSB layers and a core polystyrene foam layer.

◎ Stiff basis - for thermal panels

◎ Formwork Plywood - Overlayed OSB panels can be used repeatedly as a concrete formwork.

◎ Plank - Stairs, landings, scaffoldings

◎ Fence - temporary construction site fencing.

◎ Partition wall - partition walls for ships and railcars

◎ Structures for auto vehicles, trailer floorings and truck bodies

◎ Packing - Shipping crates and pallets packing materis.

◎ Deck - shelving units, exhibition stands, furniture shelves, shop counters, table tops, bill boards.

◎ DIY

| Type | Size | Layer up | Weight (kg/sheet) | Core Materials | Packing Unit (sheets) | ||||||

| T&G | 1220x2440x12mm | cross-oriented | 22 | Mixed Combi | 65 or 75 | ||||||

| T&G | 1220x2440x15mm | cross-oriented | 27.5 | Mixed Combi | 45 or 60 | ||||||

| T&G | 1220x2440x18mm | cross-oriented | 33 | Mixed Combi | 43 or 50 | ||||||

| T&G | 1220x2440x21mm | cross-oriented | 38.5 | Mixed Combi | 37 or 45 | ||||||

| T&G | 1220x2440x25mm | cross-oriented | 46 | Mixed Combi | 31 or 37 | ||||||

| T&G | 1220x2440x28mm | cross-oriented | 51.5 | Mixed Combi | 27 or 32 |

| FORMALDEHYDE EMISSION:E0 ≤0.03 | |||||||||||

| Layer up:Cross-oriented | |||||||||||

| Moisture Content:8% – 15% (at time of despatch) | |||||||||||

| Dimensional Tolerances:±0.3mm | |||||||||||

| Straightness:±1.5mm | |||||||||||

| Density:580 kg/m³ (approximately) | |||||||||||

| Adhesive:E0 | |||||||||||

| Joint Group:For nails, bolts and screws | |||||||||||

| Finish:Unsanded faces, sanding / T&G / paint edges. | |||||||||||

| Branding:Each pallet of PANDAFOREST OSB is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards | |||||||||||

| Storage:Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | |||||||||||

| Source:Plantation timber |

Apart from the regular standard dimensions of 1220mm x 2440mm, also special thickness lengths are available (thickness form 6mm-28mm, max lengrh 6000). Special dimensions available by request – there may be requirements for minimum quantity per special dimension.

We can provide OEM orders according to your requirements and work with you to build your own film faced plywood brand. Please contact our OEM Service Team.